Tank Integrity Testing Service

Optimal Performance with Tank Integrity Testing

Safeguard your assets and optimise tank performance with JWH Tank Services. We deliver comprehensive tank inspection and assessment solutions across the UK, serving clients in the oil and gas, petrochemical, power generation and other industries.

To protect your environment and ensure the safety of your operations, contact JWH Tank Services today for a free consultation. 01132 635163 or email [email protected]

Comprehensive Tank Integrity Assessments

- Magnetic Particle (MPI) Testing: Detects surface cracks and defects in ferromagnetic materials.

- Dye Penetrant (DPI) Testing: Identifies surface cracks and discontinuities in non-porous materials.

- Ultrasonic Thickness Testing (UT): Measures tank wall thickness to assess corrosion and erosion.

- Radiographic Testing (RT): Detects internal defects and corrosion using X-rays or gamma rays.

- Radiographic Testing (RT): Detects internal defects and corrosion using X-rays or gamma rays.

- Eddy Current Testing (ECT): Evaluates the conductivity of materials to detect defects and corrosion.

- Level Gauging: Accurate measurement of tank contents for inventory management and safety.

- Tank Cleaning & Lining: Thorough removal of contaminants and application of protective coatings to extend tank life.

- API 510 / API 570 Inspections: Adherence to industry standards for tank inspection, repair, alteration, and re-rating.

- Tank Monitoring: Continuous monitoring of tank condition for early detection of issues.

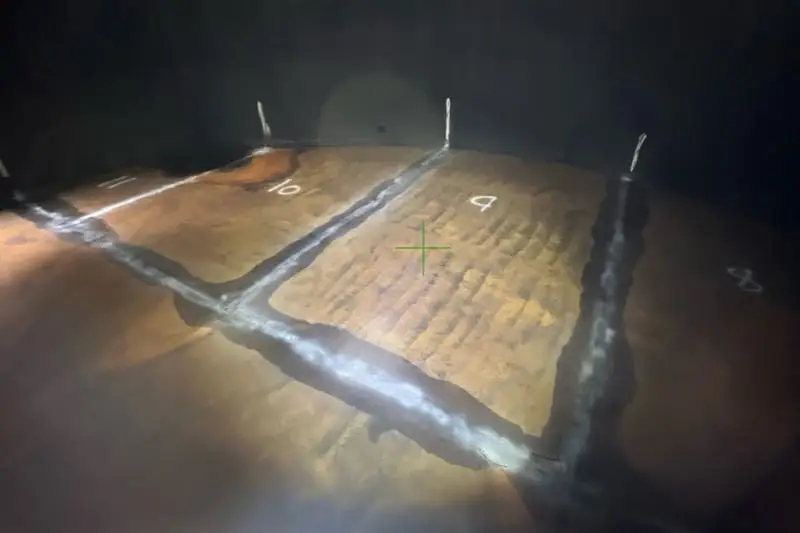

- Underwater ROV Inspections: Inspection of submerged tank components and structures.

- Drone Inspection: Using unmanned aerial vehicles for external and internal tank inspections, providing high-resolution data and enhanced safety.

- EEMUA 159 Assessments: Detailed tank integrity assessments for compliance and safety. Fuel Sampling & Disposal: Safe and compliant handling of fuel samples.

- Fuel Polishing & Gauging: Removal of contaminants from fuel and accurate fuel level measurement.

- API 653 Consultancy: Expert guidance on tank repair, alteration and maintenance.

- Welding and Fabrication: Repair and modification of tank components.

- Hydrotesting: Pressure testing to assess tank integrity.

- Settlement Surveys: Monitoring tank movement and foundation stability.

Why Choose Us?

Safety First

Your safety is our top priority. We adhere to the highest industry guidelines to ensure safe and environmentally responsible practices throughout the removal process. This commitment guarantees the protection of both our team members and the environment while delivering a personal service.

Tailored Services

No two projects are the same, which is why we customise our services to meet your unique needs. Our safe systems of work are designed by our own in-house team for each and every project. We build long-term partnerships based on trust and reliability.

Advanced Technology

State-of-the-art equipment for efficient and precise inspections.

Expertise

Our skilled technicians are certified and experienced in delivering accurate and reliable inspection results.

Tank Locations We Work In

We have experience working on tanks in various locations, such as basements, schools, office buildings, shopping centres and many more. Visit our Case Studies page to find out more.

Compliance

JWH have a proud commitment to high standards, ensuring that every aspect of the job is handled with care and expertise. Our numerous SSIP and safety accreditations demonstrate our commitment to a safe and sustainable operation.

Our Locations

With offices strategically located in Leeds, Bristol, Manchester, and Daventry, JWH Tank Services offers nationwide coverage and expert tank solutions.

Direct Communication

We provide direct access to our team for any questions or concerns throughout the tank removal process. For a no-obligation quotation or to discuss your tank removal needs, please get in touch with us via any of the methods on our Contact Page

TANK INTEGRITY TESTING FAQs

The frequency of tank inspections depends on various factors, including tank age, material, storage contents and industry regulations. We recommend conducting regular assessments to identify potential issues early on.

Our team will provide a detailed report outlining the findings and recommended actions. We offer repair and maintenance services to address any identified issues promptly.

Signs of tank deterioration include leaks, corrosion, bulging or sagging. Regular inspections can help identify these issues before they become critical.

The duration of an inspection depends on the size and complexity of the tank. We provide estimated timelines during the initial assessment.

The cost of a tank inspection varies based on the size, complexity and scope of the assessment. We offer competitive pricing and customised packages to suit your budget.

The FAQs provided are general in nature and can apply in the UK, but it’s important to note that specific regulations and procedures for fuel tank removal may vary by region and local authorities within the UK. To get accurate and region-specific information, you should consult with local environmental agencies, authorities, or tank removal professionals who are familiar with the specific requirements in your area of the UK.

In the UK, regulations related to fuel tank removal, environmental impact assessments, permits and disposal of hazardous materials are subject to the control and guidance of organisations like the Environment Agency (EA) or equivalent bodies in Scotland, Wales and Northern Ireland. They may have their own specific guidelines and procedures.

Therefore, while the general FAQs can provide a starting point, it’s crucial to ensure compliance with local regulations and seek advice from local authorities or experts who are knowledgeable about the specific requirements in your area of the UK.

Nationwide Commercial Tank Services

From Scotland to Cornwall, JWH Tanks delivers top-tier commercial tank services throughout all areas of the UK. Our commitment to nationwide coverage ensures that businesses everywhere can access our expertise. Our coverage includes:

Our Accreditations