Fuel Polishing

FUEL POLISHING

Service Overview

Our fuel polishing service is just one of a series of remedial solutions we can offer. This is usually following the identification of contaminated fuels through our fuel sampling programme.

When combined with tank cleaning, fuel polishing can reduce equipment breakdowns, and lower costs on consumables such as filters and injectors.

The need for fuel polishing can arise from a multitude of scenarios, the most common of which is a build up of water and sludge in the base of a tank over a period of years.

The waste in the tank then reacts with today’s modern blend of fuels to produce bacterial growth. This is commonly known as diesel bug, you can click here for a blog post on the subject.

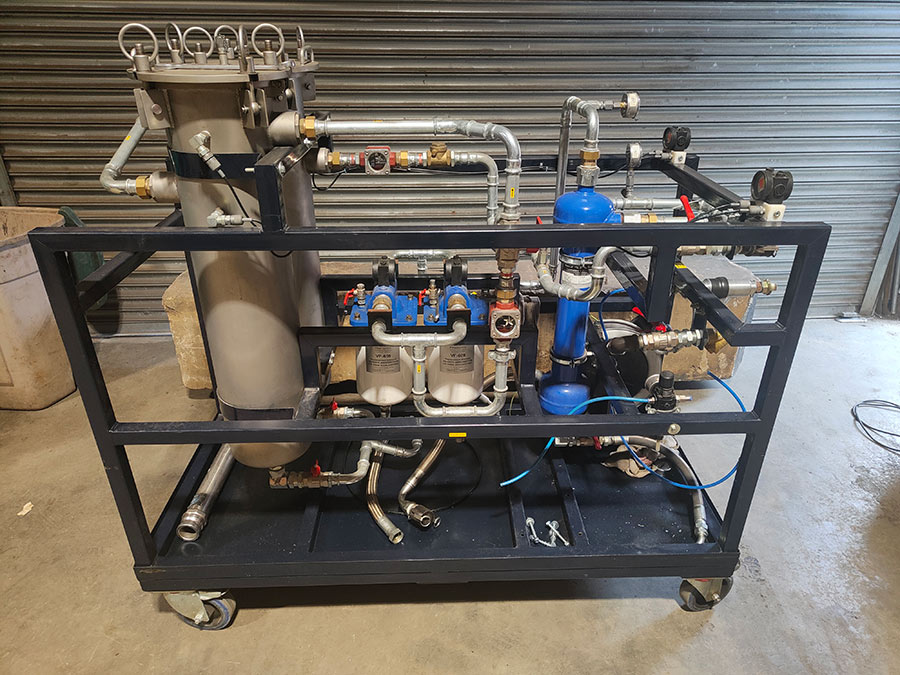

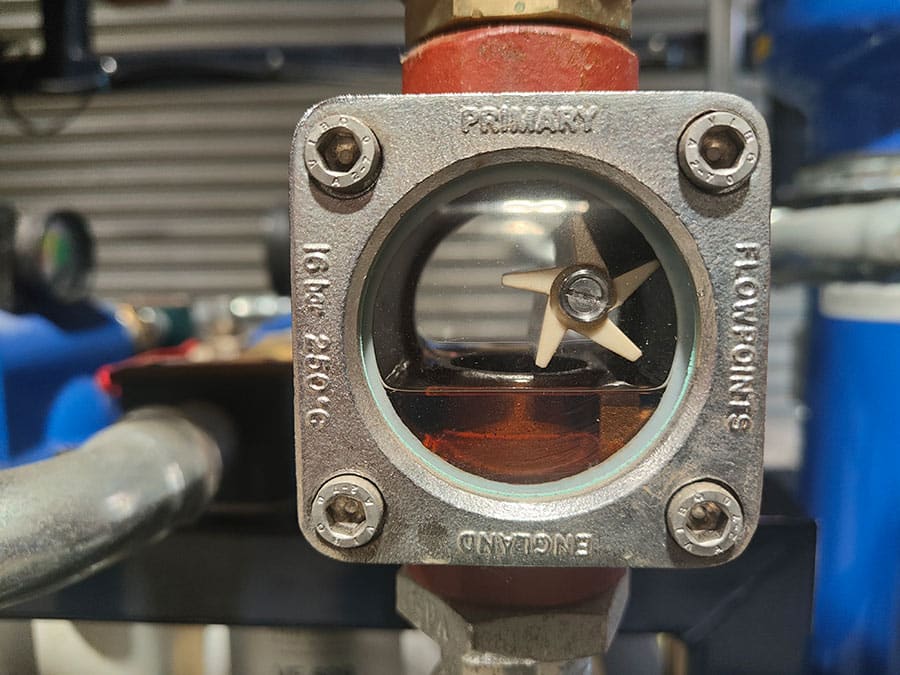

Our range of accessible equipment allows us to offer both small and large scale services. As a result, we have the ability to filter and polish an array of fuel quantities, ranging from 3000 litres per hour up to 10,000 litres per hour.

FUEL POLISHING

Fuel Polishing Into A Tank

A point to consider is the tank in which your clean fuel is being returned to. Fuel tanks are inherently dirty environments, which are incredibly difficult to empty without accessing it internally. Therefore, putting polished fuel back into a dirty tank can often defeat the object of the exercise. We would always recommend thoroughly cleaning the tank during the process.

By cleaning the tank prior to returning the fuel, we are ensuring that your polished product remains clean rather than potentially becoming contaminated again.

Click here for some information on our in-house tank cleaning services.

FUEL POLISHING

Once the process has been completed, and your clean fuel is being returned to your clean tank, we’ll then take another sample in order to gain independent labratory analysis of the product. Giving you peace of mind that the fuel stored in your tanks is of optimum quality.

To speak directly to one of our team regarding fuel polishing, or any of our services, please call 01132635163, email [email protected] or simply use our contact form.

WHY CHOOSE US FOR FUEL POLISHING?

For over 40 years we have been offering safe, reliable and cost effective petrol or diesel tank cleaning, oil tank cleaning, oil, diesel and petrol tank removal and tank disposal nationwide. Attracting a wide spectrum of clients from The Armed Services and Local Authorities, to the Construction Industry, Independent Petroleum Retailers and Domestic Households.

- 40 years experience

- Reliable and cost effective

- In-house team

- The highest standards

- On time and on budget

- Real focus on Customer Satisfaction

SERVICE FAQs

Not all fuel needs to be polished, and there are a number of factors. If you are using fuel reasonably quickly, then polishing probably isn’t for you. If you are storing fuels for a period of time e.g. for back up power generation, you may well be sitting on that fuel for months at a time. At this point, a sampling regime can give you the information you need in regards to the quality of your fuel, and whether a polish can help.

Our preferred method of polishing would be to completely empty any storage tank of fuel, to allow our engineers to clean the tank internally. This allows our team to inspect the tank internals, and also ensures that clean fuel is not being returned to a dirty tank. For instance the fuel could become contaminated further if remixed with sludge. Once the work has been completed, a sample of the polished fuel will be taken and sent for independent lab analysis.

Depending on the amount of fuel to be polished, the process gen generally be completed within a day, including opening and internally cleaning a bulk storage tank. Our teams will work with you in order to establish the ideal methodology to prevent disruption to your organisation.

Our Accreditations