Fuel Polishing

Optimise Your Fuel Quality

Our fuel polishing service offers a reliable and cost-effective solution to ensure your stored fuels remain clean, efficient and free from contaminants. We understand the critical importance of maintaining high-quality fuel for your operations, which is why our fuel polishing services are designed to address a variety of fuel-related issues.

The Benefits of Fuel Polishing

Fuel quality is paramount for equipment efficiency and longevity. Over time, fuel storage tanks can accumulate water, sludge and impurities. This can lead to bacterial growth commonly referred to as “diesel bug”. This contamination can cause equipment breakdowns, increased consumable costs (filters, injectors) and decreased fuel efficiency.

Our fuel polishing service is often recommended following our fuel sampling program, which identifies fuel contamination issues. By combining fuel polishing with tank cleaning, we can significantly reduce equipment-related problems and ensure the longevity of your machinery.

Comprehensive Fuel Polishing Service

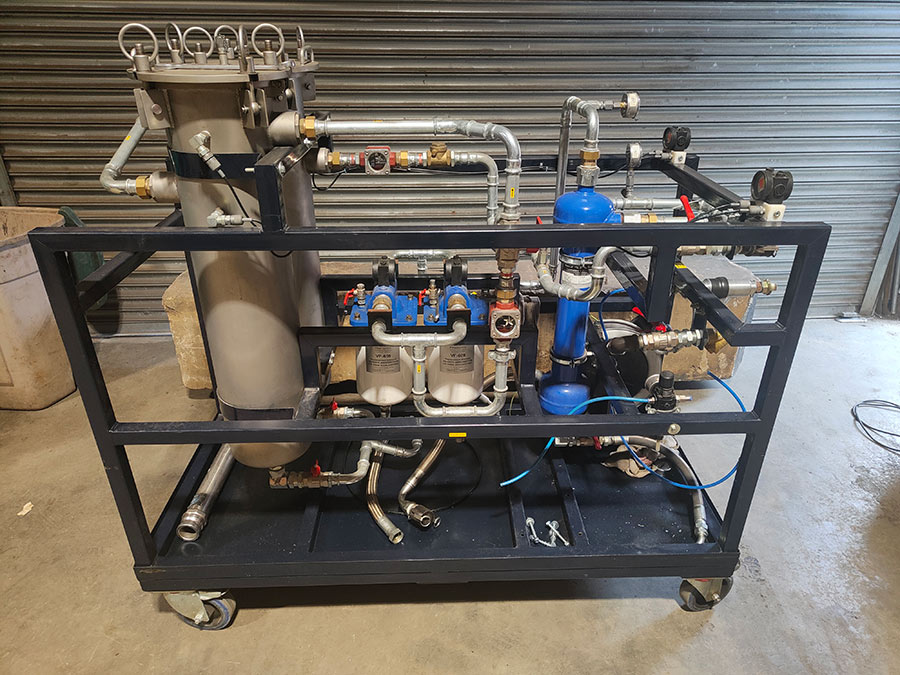

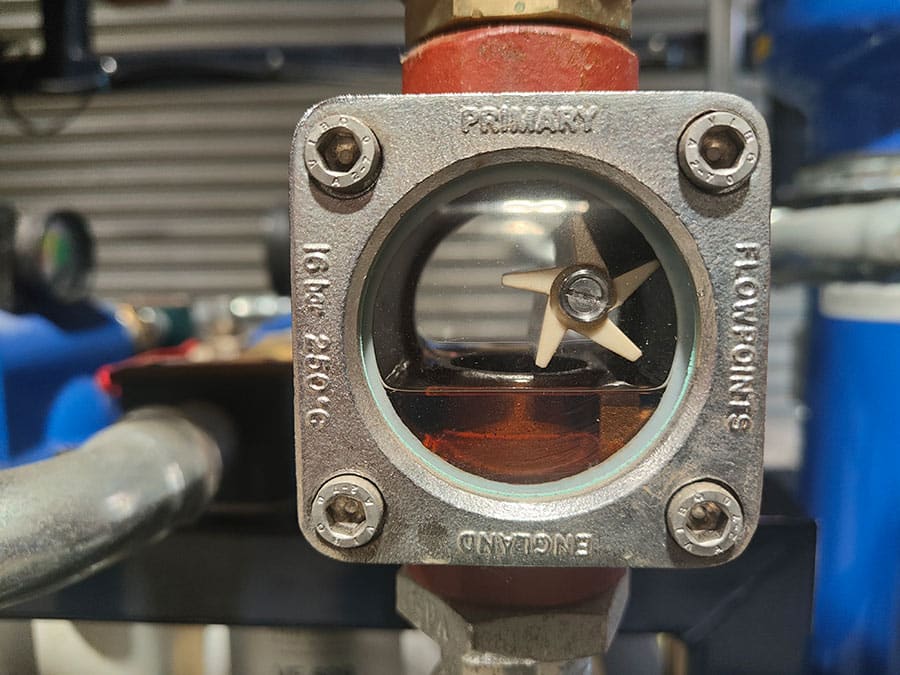

Our range of specialised equipment enables us to provide fuel polishing services for both small and large-scale needs. We can filter and polish fuel quantities ranging from 3,000 to 10,000 litres per hour, accommodating a wide range of fuel storage capacities.

Clean Fuel Needs a Clean Tank

One essential consideration during fuel polishing is the condition of the tank where the clean fuel will be returned. Fuel tanks can be inherently dirty and challenging to empty without internal access. To maximise the benefits of fuel polishing, we recommend thoroughly cleaning the tank during the process. Cleaning the tank before returning the polished fuel ensures that your product remains clean and free from potential contamination.

Independent Lab Analysis for Quality Assurance

Upon completing the fuel polishing process and returning the clean fuel to your tank, we conduct another sample to undergo independent laboratory analysis. This step provides you with the assurance that your stored fuel meets the highest quality standards.

CONTACT US TO DISCUSS FUEL POLISHING

If you would like to discuss your Fuel Polishing with one of our experienced engineers, please feel free to call us on 0113 2635163 , email [email protected] or fill out our enquiry form.

WHY CHOOSE JWH FOR COMMERCIAL FUEL POLISHING?

Backed by over five decades of industry expertise, JWH is well-placed to understand the critical importance of maintaining clean, efficient and contaminant-free stored fuels for your operations.

- Expertise in Fuel Quality

- Comprehensive Solutions

- State-of-the-Art Equipment

- Prioritising Clean Tanks

- Quality Assurance

- Project Management

With a deep understanding of the impact of fuel quality on equipment efficiency and longevity, we are experts in the field. We address common fuel issues such as water, sludge, and impurities that accumulate in storage tanks over time, leading to bacterial growth known as “diesel bug.” Our fuel polishing services are designed to resolve these problems effectively.

We offer a comprehensive fuel polishing service that goes beyond surface-level solutions. Our approach combines fuel polishing with tank cleaning to deliver a holistic solution. By doing so, we not only enhance the quality of your fuel but also significantly reduce equipment breakdowns, lower consumable costs (filters, injectors), and improve fuel efficiency.

Our specialised equipment sets us apart. We have the capability to filter and polish fuel quantities ranging from 3,000 to 10,000 litres per hour, making us well-equipped to handle various fuel storage capacities.

One crucial aspect of fuel polishing is the condition of the tank receiving the clean fuel. Many fuel tanks are inherently dirty and challenging to clean without internal access. To ensure that your polished fuel remains uncontaminated, we recommend thoroughly cleaning the tank during the process. This step is essential to maximise the benefits of fuel polishing.

To provide you with the highest level of assurance, we conduct independent laboratory analysis on the fuel after the polishing process is complete. This analysis confirms that your stored fuel meets the most stringent quality standards, giving you peace of mind regarding its performance.

From project inception to completion, we manage all aspects to keep you informed and confident in the progress of your refurbishment project. Timelines, milestones, and clear communication are integral parts of our project management.

We strive to deliver services on time, within budget and with a strong commitment to customer satisfaction.

SERVICE FAQs

Not all fuel needs to be polished, and there are several factors to consider. If you are using fuel reasonably quickly, then polishing probably isn’t for you.

Fuel polishing is recommended for those storing fuel for extended periods, such as backup power generation. A sampling regime can provide insights into your fuel quality and determine whether polishing is necessary.

Our preferred method includes emptying the storage tank, allowing our team to clean it internally. After completing the work, we take a sample of the polished fuel, which is sent for independent lab analysis.

The duration varies based on the amount of fuel to be polished but typically can be completed within a day. Our team collaborates with you to minimise any disruptions to your organisation.

Yes, fuel polishing can lead to significant cost savings by extending the life of your equipment and reducing the need for frequent filter and injector replacements. Additionally, it can help prevent costly breakdowns caused by fuel contamination.

Yes, fuel polishing is beneficial to both diesel and petrol fuels. It effectively removes contaminants and ensures the quality of the stored fuel, regardless of the type.

Common signs include decreased equipment efficiency, frequent clogging of filters, increased smoke emissions, unstable engine performance and a higher rate of equipment breakdowns. If you experience any of these issues, it’s advisable to consider fuel polishing.

In most cases, fuel polishing can be conducted while your equipment is in operation. Our experienced team will work with you to determine the best approach that minimises disruption to your operations.

While there are no specific regulations for fuel polishing, it’s essential to comply with environmental regulations and safety standards when handling fuel and conducting maintenance activities. Our team ensures that all work is carried out safely and in compliance with relevant guidelines.

OUR ACCREDITATIONS