Diesel Bug – The Basics & Storage Tanks

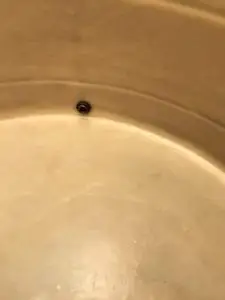

Diesel bug is term commonly referred to when discussing the slimy build up that is found when filters become blocked, primarily on dispensing pumps or machinery using diesel or gas oil.

This slimy build up or ‘diesel bug’ starts to appear as fuel begins to deteriorate, particularly when the conditions for bacterial growth are just right.

Many sources suggest that the typical lifespan for diesel in storage is between 6-12 months, assuming that no fuel maintenance programme is in place.

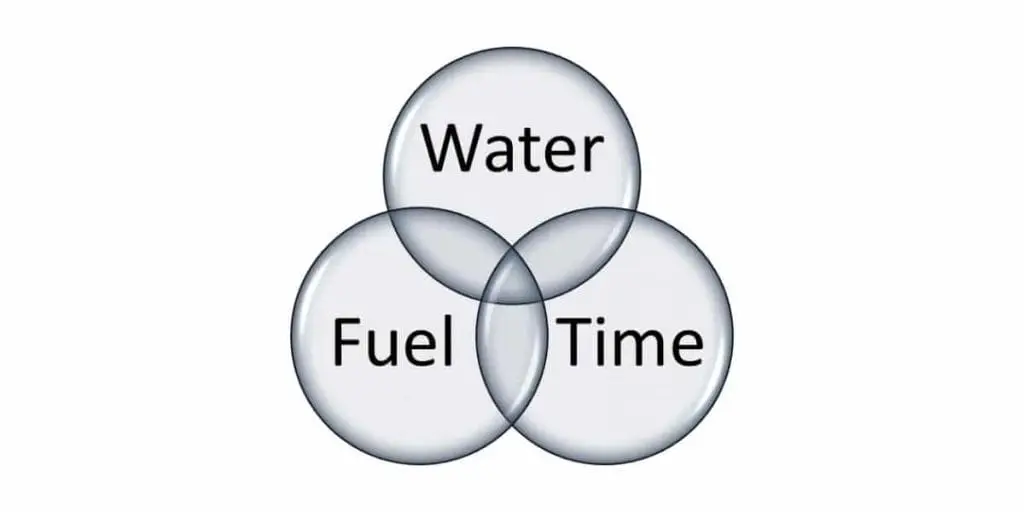

Conditions for Bacterial Growth

Water is a key factor in the growth of bacteria in a fuel tank. Although tanks are not open to the elements, water can still enter the tank through condensation arising from temperature fluctuations, and occasionally when mistakes are made e.g. lids being left open.

UK diesel can contain up to 7% bio-fuel content by today’s standards. Bio-diesel is derived from vegetable or animal fats which have been reacted with alcohols such as ethanol or methanol. Bio-diesel is hygroscopic in nature, allowing it to absorb water from the atmosphere in which it lives. This enables fuel to provide a perfect breeding ground for organisms living in the interface between the water and the fuel. Bacteria will simply extract oxygen from the water, and nutrients from the fuel in order to multiply.

With the majority of fuel systems drawing product from slightly above the base of the tank, this leads to contaminants entering the dispensing lines and causing damage to equipment.

Preventing Diesel Bug

As with any contamination issue, starting at the source is always the best way to both eradicate an existing problem, and prevent future issues, in this case, the storage tank:

Testing for water. – A number of water finding pastes are available on the market from brands such as KolorKut and Gasoila. Always check with the manufacturer to ensure you are using the correct paste for your particular fuel.

Fuel sampling. – Have samples of your existing fuel taken from different heights within the tank to establish the current condition of your fuel. This would be particularly relevant to any fuels that have been stored for a period of time. Tank cleaning. – There are numerous products on the market such as additives and polishing rigs, but a full clean of the tank allows you to be confident that standing water and sludge have been removed.

Fuel polishing. – Fuel can be passed through a series of filters, however we recommend the fuel is dispensed into a clean tank.

Implement a fuel maintenance schedule. – This can be as simple as regularly dipping your tank for signs of water, and ensuring that you don’t order more fuel than you can use in a 6-12 month period.

Talk to us about Diesel Bug

If you feel your operation may be suffering from the effects of diesel bug, please feel free to get in touch. We can offer the following services:

- Free telephone advice.

- Site visits in order to dip tanks for water.

- Collecting fuel samples for analysis at an independent UKAS accredited labratory.

- Tank cleaning.

- Fuel polishing.

Contact us now on 01132635163, by emailing i[email protected] or by using our contact form.

Information on UKAS accredited laboratories can he found here.